Results 1 to 14 of 14

-

07-28-2014, 01:47 PM #1

Electric Turbo Confirmed for S-Q7 TDI

I always used to laugh at the idea of an electric turbocharger as it always brought to mind something like this:

http://www.amazon.com/Air-Intake-Sup.../dp/B004N8W31O

But as we know Audi has been working on the electric turbocharger and it is now confirmed as a supplement to the TDI to help provide boost immediately.

http://www.leftlanenews.com/audi-con...7-in-2016.html

-Rich

-Rich Originally Posted by Leftlanenews

Originally Posted by Leftlanenews

-

07-28-2014, 02:29 PM #2

Guest Vendor

Guest Vendor

- Join Date

- Aug 2012

- Location

- Hayward, CA

- Posts

- 9,218

- Rep Points

- 3,664.1

- Mentioned

- 349 Post(s)

- Rep Power

- 0

It was only a matter of time, as electronics, and electric motors powering cars move forward at such a rapid pace this makes a lot of sense.

-

07-28-2014, 04:54 PM #3

Member

Member

- Join Date

- Sep 2012

- Posts

- 1,162

- Rep Points

- 980.2

- Mentioned

- 14 Post(s)

- Rep Power

- 10

Deff not a bad idea at all if implemented correctly. The current gen of HIgh Perf german turbo motors sure are power houses but one thing I don't like is the lack of top end power. They build the cars for response and minimal turbo lag using the smallest turbo possible and that really shows when the cars are modded and turbos run out of breath uptop. This would allow the use of a bigger turbo to increase the top end significantly but still have great response off at low rpm.

-

07-28-2014, 05:11 PM #4

I want want the motor on the shafts with variable exhaust vanes.

-

07-28-2014, 05:38 PM #5

Guest Vendor

Guest Vendor

- Join Date

- Aug 2012

- Location

- Hayward, CA

- Posts

- 9,218

- Rep Points

- 3,664.1

- Mentioned

- 349 Post(s)

- Rep Power

- 0

Why on earth would you want Variable Exhaust Vanes? No single piece of turbocharger technology has been more problematic, we get turbos in here daily with stuck, wore out, or flat out broken vanes, or vane controlling systems. Great on paper, in service they offer multiple small moving parts to fail in a 1500+ degree environment. 1500 degrees + small moving parts do not like each other for very long

-

07-28-2014, 05:51 PM #6

If they don't fail they should be awesome. I'v never had experience with them but yes on paper they are great, and great with a warranty. What percentage of commercial turbos use variable vanes would you say that you service?

They must work to some degree or people would stop using them no? Usually manufacturers figure out pretty quick if something is a reliability nightmare and stop manufacturing it.

-

07-28-2014, 06:08 PM #7

Guest Vendor

Guest Vendor

- Join Date

- Aug 2012

- Location

- Hayward, CA

- Posts

- 9,218

- Rep Points

- 3,664.1

- Mentioned

- 349 Post(s)

- Rep Power

- 0

When they are working as they are supposed to work, yes they do perform the task they are their for, quicker spool, and more top end. But from what we have seen, they are slowly getting phased out. Ford used them for a while, now they do not in the newest stuff. The ford 6.0 diesel VGT was a disaster, they get stuck often, causing low power conditions. VW used them in just about every turbocharged vehicle they made, they used Garrett unit, we just upgraded two 2015 units for a customer in South Africa, the Golf R's and the new GTI's both went away from the VGT and are no longer garrett unit. Just about everything we see if going away from them into more small frame Twin Scroll design. They really are that problematic, they are MANY small moving parts that are sitting directly in the exhaust, a lot of these are on diesels, that soot and exhaust just coat everything and they stop moving. I would not be surprised to see them gone soon. Porsche still uses them on the 997's. We have yet to see one, so they are most likely a better design, but we have seen about 10 different designs from differing manufactures, some are simple and much less prone to failure, some are just plain bad designs. I think the electric turbo to help spool is where the future would be heading over VGT.

-

07-30-2014, 11:24 AM #8

Audi's electric compressor (turbo) will see production on the 2016 Audi SQ7 TDI

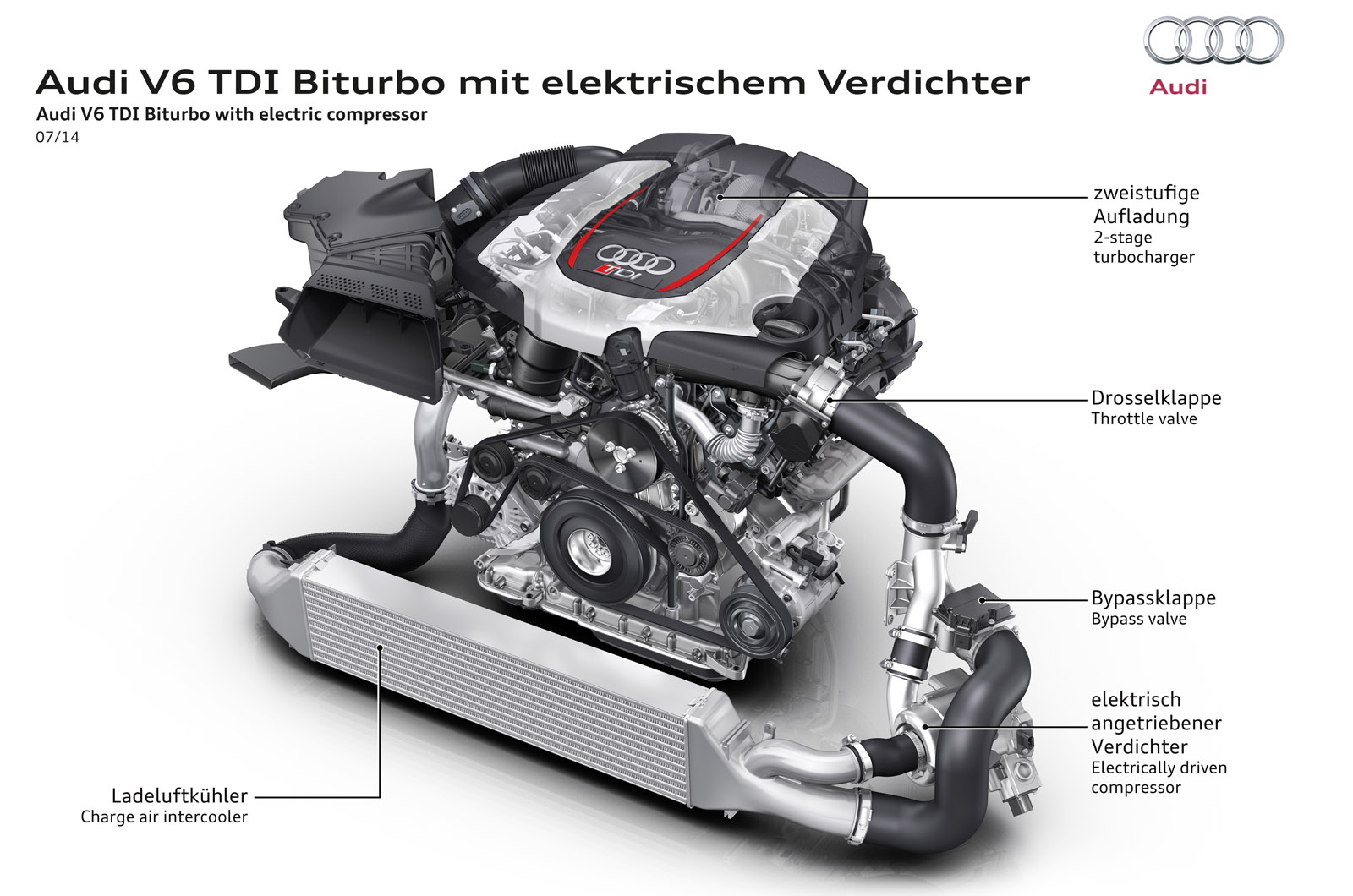

Audi showed off a triple turbocharged 3.0 liter V6 diesel motor in May of this year on the RS5 TDI concept. That engine concept is moving to reality as Audi confirmed that the engine will see production in the upcoming SQ7 TDI. What type of output the SQ7 TDI will have nobody except Audi knows at this point. In the RS5 TDI concept Audi tuned the motor to 385 horsepower and an eye opening 553 lb-ft of torque. AudiBoost has its fingers crossed the production variant of the motor approaches this output.

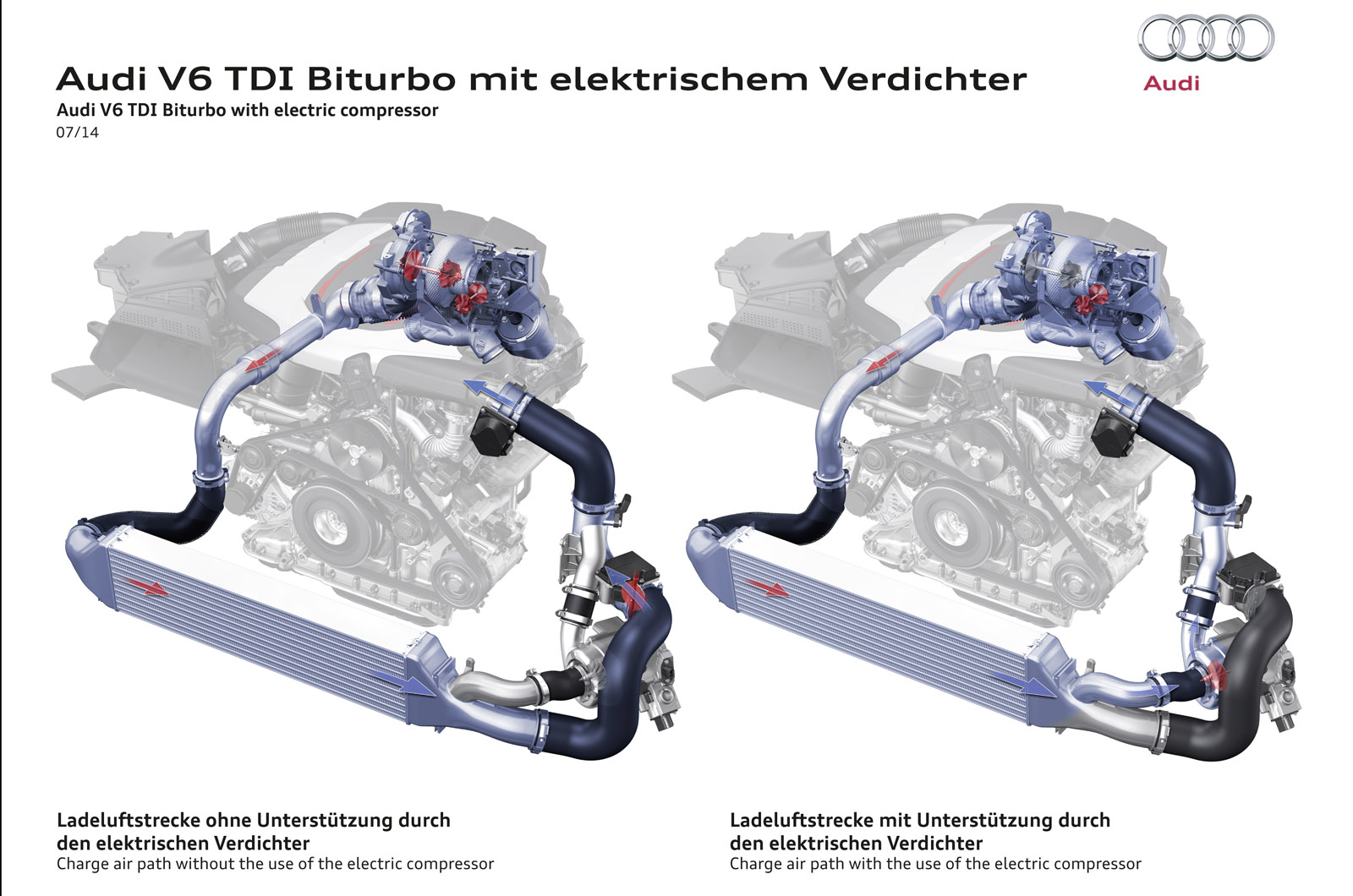

People refer to this electric compressor as a 'turbo' and that includes Audi themselves. However, an electrically driven compressor wheel is essentially an electric supercharger. The advantage is that you do not have to wait for spool from exhaust gases but that the wheel with electricity can be spun to maximum right off idle. The idea is to eliminate lag from the turbochargers which is vital in low revving diesel applications.

The electric compressor helps throttle response and off the line performance. Once the conventional turbos are spooled the electric 'turbo' is disengaged and bypassed. The question remains on how Audi intends to power the 9 horsepower electric motor spinning the wheel and where that energy will be stored. The engineers will sort all of that out.

The diagrams below help explain how the idea works.

SourceBRAND NEW IN BOX 991.2 standard/non-pse SPW cat bypass pipe for sale - $899 shipped

New generic 991.2 PSE bypass pipes - $499 shipped

-

07-30-2014, 11:47 AM #9

Guest Vendor

Guest Vendor

- Join Date

- Aug 2012

- Location

- Hayward, CA

- Posts

- 9,218

- Rep Points

- 3,664.1

- Mentioned

- 349 Post(s)

- Rep Power

- 0

Compound twins, and an electric motor to help eliminate spool, sounds like a whole lot of stuff to go wrong.

-

07-30-2014, 12:25 PM #10

Member

Member

- Join Date

- Apr 2011

- Location

- Jersey City

- Posts

- 3,850

- Rep Points

- 3,654.6

- Mentioned

- 75 Post(s)

- Rep Power

- 37

You don't want variable exhaust vanes. Detroit diesel put them on thier 2004-2008 EPA series 60 engines and they were nothing but problems. My company made money swapping them out when they failed but the downtime associated with them was terrible. I imagine in a car they would be just as bad.

ESS 6XX kit

-

07-30-2014, 01:26 PM #11

Member

Member

- Join Date

- Apr 2013

- Location

- SoCal

- Posts

- 41

- Rep Points

- 43.1

- Mentioned

- 0 Post(s)

- Rep Power

- 0

Coming to think of it, turbochargers recycle some exhaust energy at the expense of increased backpressure. Also, and correct me if I am wrong, the main reason why the turbochargers are as close as they are to the engine is for their direct coupling into the intake. If the turbines are used instead as electrical generators then the location does not need to be as close to the engine as it is which could reduce the thermal stress quite a bit and remove the need of wastegates. If anything, if the battery is used as a buffer to recycle the exhaust flow energy it makes more sense for them to be in the rear (where the battery is located), from electrical stand point. The recycled energy can be used to power the electrical compressor and increase efficiency overall (less load on the crankshaft coupled generator). Another advantage of the electrical compressor that I can think of is that it is decoupled from the crankshaft which imposes certain limitations to superchargers, generally speaking. The downside – increased weight. Oh well, this is just the 2c of an electrical engineer with a limited knowledge in IC engines.

-

07-30-2014, 01:43 PM #12

What about the main downside of it not providing as much power? There is a reason it is disconnected from the system as soon as it can be.

BRAND NEW IN BOX 991.2 standard/non-pse SPW cat bypass pipe for sale - $899 shipped

New generic 991.2 PSE bypass pipes - $499 shipped

-

07-30-2014, 02:00 PM #13

Member

Member

- Join Date

- Apr 2013

- Location

- SoCal

- Posts

- 41

- Rep Points

- 43.1

- Mentioned

- 0 Post(s)

- Rep Power

- 0

Well, I do not know where they plan to get the 9HP to power the compressor. What I typed above is just an idea. Since they are still using conventional turbos I'd guess they do not recycle energy the way I mentioned above which would limit the use of the electrical compressor for bursts or to eliminating spool only. If they were to use it at all times, given it can provide enough flow and pressure, the electrical system should be redesigned and derated quite a bit to accommodate sustained current draw, which would be probably more R&D than what they are willing to do in their development cycle . It appears that they are looking mostly at eliminating spool which is one of the main drawbacks of TC. What I typed above could in theory improve efficiency and maybe even improve reliability due to highly reduced thermal stress, but I am really just speculating. It's not like I built any of the above

-

06-21-2015, 01:33 AM #14

Timeout

Timeout

- Join Date

- Apr 2014

- Location

- ATL

- Posts

- 3,192

- Rep Points

- 2.1

- Mentioned

- 18 Post(s)

- Rep Power

- 0

Quote

Quote

mikasalo5000,...

We welcome mikasalo5000